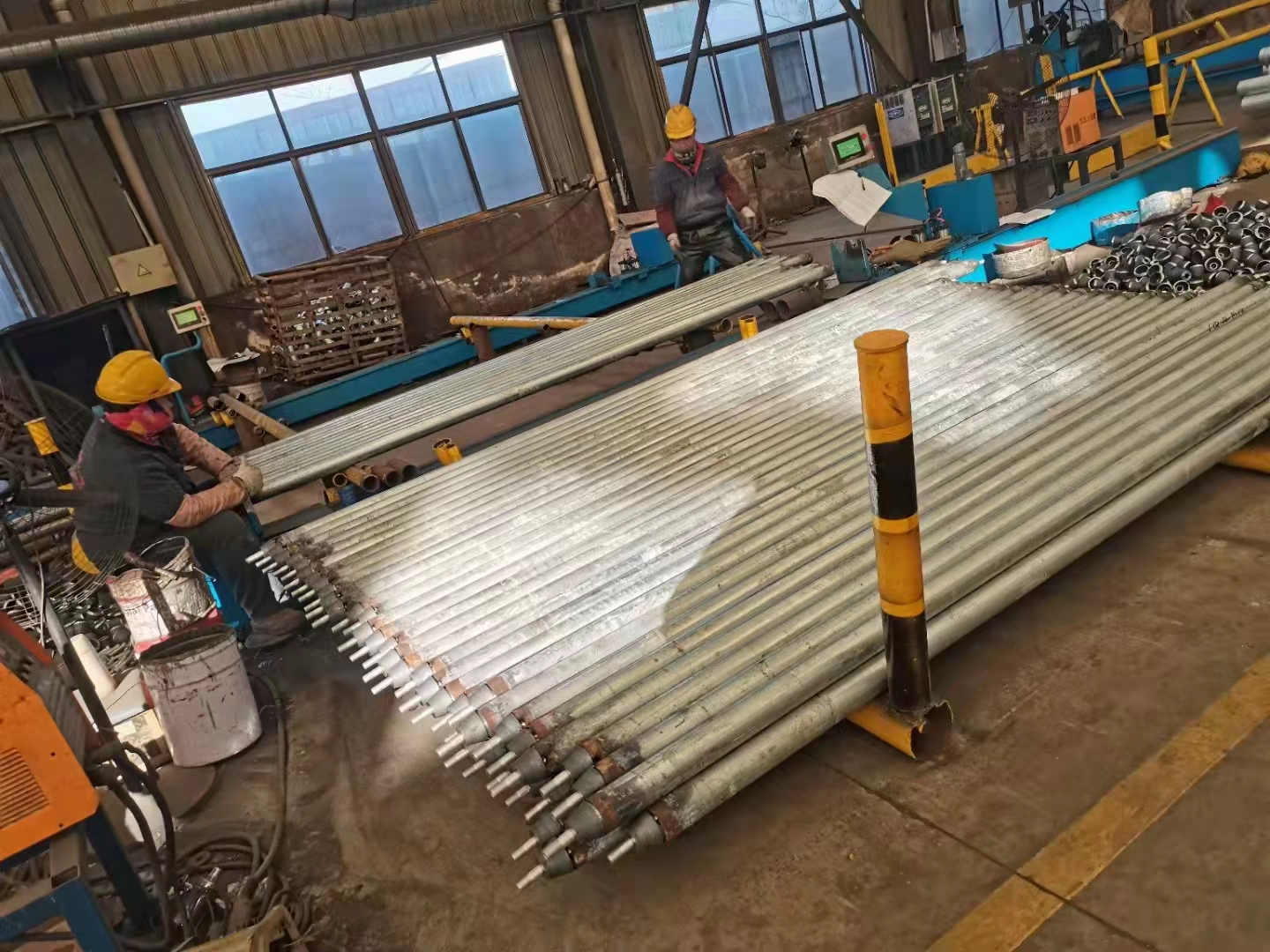

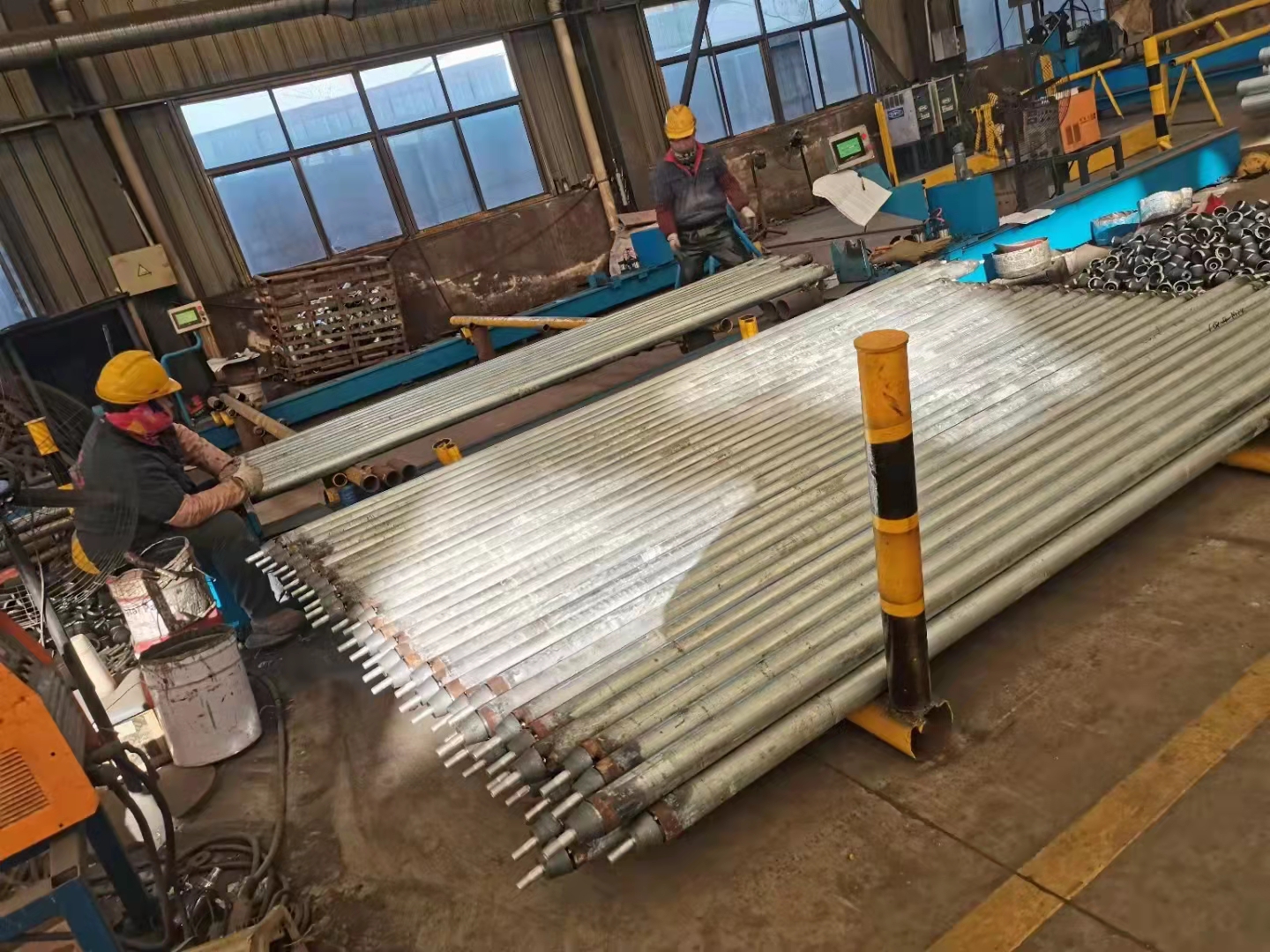

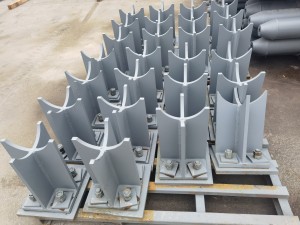

steel qhov chaw ncej blanking txheej txheem

txiav:

A.Cov neeg ua haujlwm tsim kho yuav tsum ua tib zoo xyuas cov duab kos, thiab yog tias pom muaj teeb meem, lawv yuav tsum tau tsa tam sim ntawd rau tus neeg saib xyuas kom tsis txhob muaj teeb meem.

daws qhov teeb meem hauv lub sijhawm.

B. Qhov loj ntawm cov nodes tseem ceeb yuav tsum tau staked tawm los yog xam.

C. Cov cuab yeej ntsuas uas siv rau hauv stakeout, blanking thiab cov khoom sib dhos thiab kev tshuaj xyuas yuav tsum yog cov cuab yeej ntsuas tsim nyog tau lees paub los ntawm lub tuam tsev ntsuas thiab ntsuas.

D. Cov kab txiav rau blanking yuav tsum yog qhov tseeb thiab meej, nrog cov nyiaj pub dawb rau vuam shrinkage thiab txiav ntug ua.

E. Kev txiav cov khoom yuav tsum raug txiav los ntawm lub tshuab shearing, nplaim taws txiav tshuab, ua ke xuas nrig ntaus thiab shearing tshuab, hneev sawing tshuab, thiab lwm yam., nyob ntawm seb qhov xwm txheej tshwj xeeb, thiab phau ntawv txiav yuav tsum zam kom ntau li ntau tau.Saib lub rooj rau qhov tso cai sib txawv ntawm ntau txoj kev txiav thiab txiav qhov chaw

F. Hauv zos nicks nrog qhov tob ntawm ntau tshaj 1 hli ntawm qhov chaw txiav, txiav nrog qhov tob ntawm ntau tshaj 2 hli, thiab cov seem

Qhov seem burrs yuav tsum tau kho thiab polished.

| Txoj kev txiav thiab tso cai sib txawv ntawm kev txiav nto | |

| Lub npe qhov project | Ua siab ntev |

| Tsis siv neeg thiab semi-automatic txiav | ± 1.5 hli |

| Qhov tsis yog-perpendicular txoj kab nqes ntawm qhov chaw txiav yog | ≤1.5 hli |

| Txiav bevel kaum sab xis | ± 3° |

| Txiav ntug dullness | ± 2.0 hli |

| Tes txiav | ± 2.0 hli |

G. Daim ntawv welding zawj ntawm cov khoom yuav tsum raug xaiv raws li cov cim vuam cim ntawm daim duab kos thiab daim ntawv zawj thiab qhov loj me.